Solid-liquid separation The ultimate goal of the is to completely separate solid and liquid to obtain their own pure ingredients. According to the current development, solid-liquid separation can be basically divided into two methods: sedimentation separation and filtration separation. Sedimentation separation can be divided into gravity sedimentation and centrifugal sedimentation.

1. Settlement separation:

Sedimentation and separation depend on the movement of solid particles. In this process, solids transition from highly dispersed state to concentrated state. In sedimentation separation, the lower the concentration of solid particles is, the better the separation is. On the contrary, the liquid phase moves during filtration, so the smaller the liquid content is, the higher the solid concentration is, which is conducive to separation.

a. Principle of gravity settlement:

It is theoretically the most economical method to use gravity sedimentation characteristics to separate liquids, which is driven only by gravity and does not require additional energy. It is necessary to provide sufficient settling area to accelerate the terminal settling speed of solid particles. Coagulates and flocculation techniques are often required. For suspensions composed of smaller particles and higher viscosity solutions, flocculation technology alone is often difficult to meet the requirements of solid-liquid separation, so it is necessary to introduce artificial centrifugal force to enhance the driving force of solid particle sedimentation, namely centrifugal sedimentation.

b. Principle of centrifugal sedimentation:

Centrifuge technology is to use the strong centrifugal force generated when the object rotates at a high speed to make the suspended solids in the rotating body settle or float, so as to achieve the purpose of concentration or separation from other particles. The solid particles with mass m suspended in the liquid rotate at high speed Centrifuge The force applied along the radial direction is:

Where Fr is the centrifugal radius of the particle, ω Is the rotational angular speed, and n is the rotational speed. The above formula shows that the centrifugal force is proportional to the square of rotating speed and the distance r of particles from the axis. The separation factor is the ratio of centrifugal force to gravitational force.

2. Filtering and separation:

Filtering usually uses some medium to block or intercept the solids in the suspension to achieve the purpose of solid-liquid separation. Solid particles are trapped upstream of the medium, and liquid is collected downstream of the medium. According to the different filtering media and methods currently used, the filtering mechanism can be basically divided into four types: surface blocking, deep blocking, deep filtering and cake filtering. The filter media can usually capture many particles smaller than the pore size of the media, depending on the nature of the media. At the same time, the above mechanisms can coexist and interact with each other. The liquid also affects the filtration performance.

3. Membrane separation:

The membrane separation process is usually carried out at ambient temperature. By applying pressure, concentration difference, voltage difference, etc. on both sides of the membrane, the mixture on both sides of the membrane can realize material transfer in the desired direction.

In summary, solid-liquid separation methods mainly include sedimentation and filtration, and sedimentation can be divided into gravity sedimentation and centrifugal sedimentation. According to the specific separation requirements and material characteristics, selecting appropriate separation methods and equipment can effectively realize solid-liquid separation and meet the requirements of production and treatment.

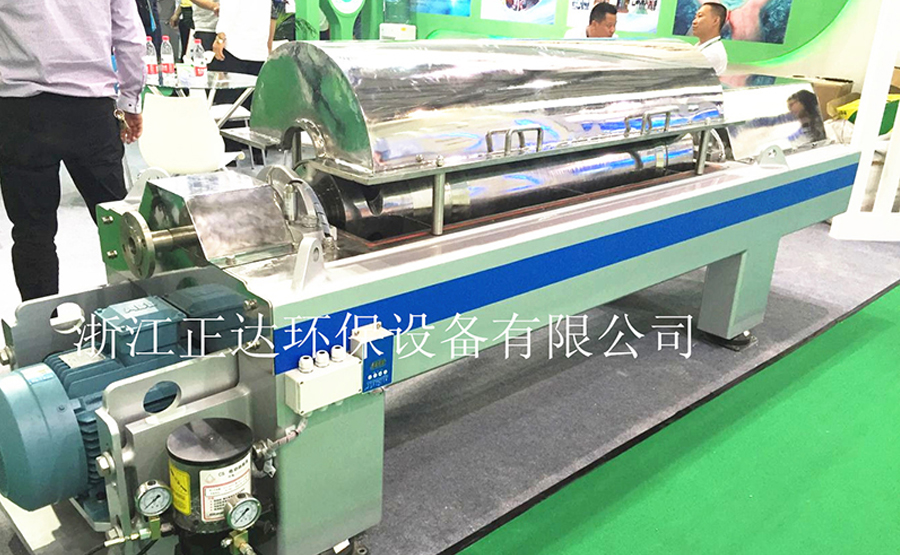

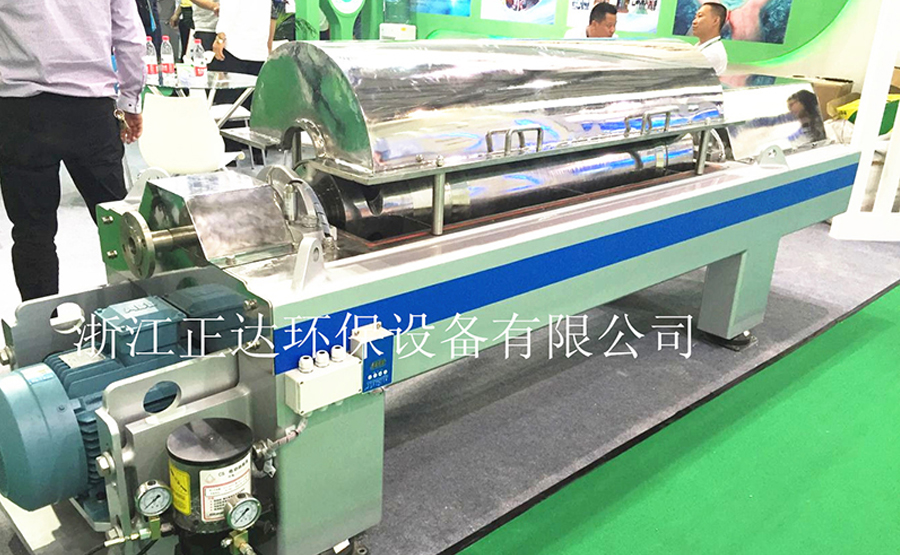

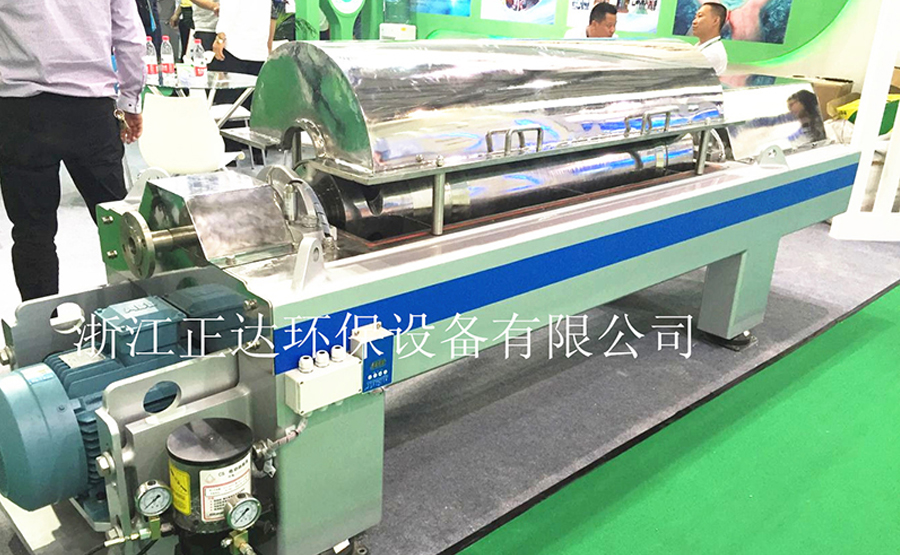

Zhejiang Zhengda Environmental Protection Equipment Co., Ltd.: focusing on Horizontal spiral sedimentation centrifuge, sludge dewatering machine, sludge treatment equipment, centrifugal dewatering machine, sludge dewatering equipment, solid-liquid separation equipment, horizontal spiral centrifuge, centrifuge, mud dewatering machine, mud dewatering equipment, mud treatment equipment, horizontal centrifuge, solid-liquid separator Production, sales and service of various solid-liquid separation equipment. Welcome new and old customers to come for consultation and investigation.

Factory address: No. 812, Jiulong Street, Bihu Town Industrial Zone, Liandu District, Lishui City, Zhejiang Province Telephone: 0578-2788008 Fax :0578-2788681

Email: [email protected] website: //hcsxe.com

Mobile: 15857812218 (Mr. Mao) fifteen billion two hundred and fifty-seven million eight hundred and twenty-six thousand six hundred and nine (Manager Xu) thirteen billion nine hundred and six million seven hundred and eighty-eight thousand three hundred and sixty-seven (Mr. Xu)