I Horizontal screw centrifuge

Horizontal spiral sedimentation Centrifuge Referred to as horizontal spiral centrifuge, it is a highly efficient Centrifugal separation equipment 。 Horizontal spiral centrifuges can generally be divided into horizontal spiral filtration centrifuges and horizontal spiral sedimentation centrifuges. Horizontal screw centrifuge is a kind of horizontal spiral discharge and continuous operation settling equipment. The working principle of this type of centrifuge is that the drum and the screw rotate at a certain differential speed in the same direction at a high speed, and the materials are continuously introduced into the inner cylinder of the feeding screw through the feeding pipe, and then enter the drum after acceleration. Under the action of the centrifugal force field, the heavier solids are deposited on the drum wall to form a sediment layer. The material conveying screw continuously pushes the deposited solids to the cone end of the drum and discharges them out of the machine through the slag discharge port. The lighter liquid phase substances form an inner liquid ring, which continuously overflows the drum from the overflow port at the big end of the drum and is discharged out of the machine through the liquid outlet. The machine can continuously feed, separate, wash and discharge materials at full speed. It is characterized by compact structure, continuous operation, stable operation, strong adaptability, large production capacity, convenient maintenance, etc. It is suitable for separating suspensions containing solids with particle size greater than 0.005mm and concentration range of 2-40%. It is widely used in chemical industry, light industry, pharmacy, food, environmental protection and other industries.

II Vertical centrifuge

Vertical centrifuge is an efficient Solid liquid separation equipment 。 The vertical centrifuge is composed of a feeding device, a separation system, a filtering bin, a discharging bin, a transmission system, a washing device and an electric control device. The whole system of the vertical centrifuge ingeniously applies the double effects of centrifugal force and gravity to realize the continuous work of the equipment and achieve high work efficiency. The slurry enters the centrifuge from the feed inlet. Under the action of centrifugal force in the separation system, the solid is trapped through the filter screen. The liquid passes through the screen and enters the filter bin and is discharged from the mother liquor outlet. The solid moves downward under the component force of gravity and centrifugal force, and enters the lower level section through the discharge bin. In the process of movement, the washing system pumps washing liquid to wash solids. All power is driven by a motor. During the separation process, the residence time of solids in the separation system can be controlled by adjusting the feed speed and the relative position of each part of the separation system to meet the specified water content requirements for solids.

3、 Filter

The filter is a device that uses porous filter media to intercept the solid particles in the mixture of liquid and solid particles to realize the separation of solid and liquid. Filters are widely used in chemical, petroleum, pharmaceutical, light industry, food, mineral processing, coal and water treatment sectors.

The above three types of solid-liquid separation equipment are the most common. In the interim, the horizontal spiral centrifuge is the most widely used, and the solid-liquid separation effect is relatively stable. High cost performance

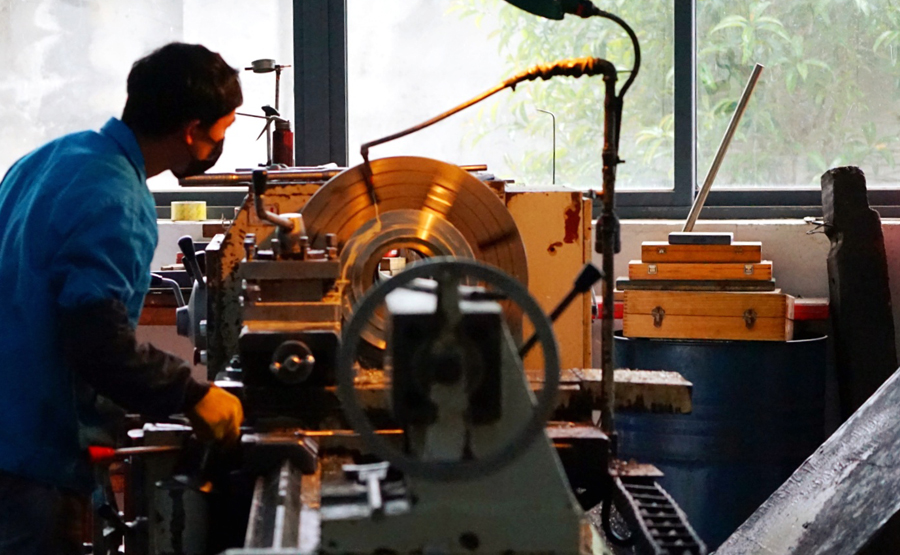

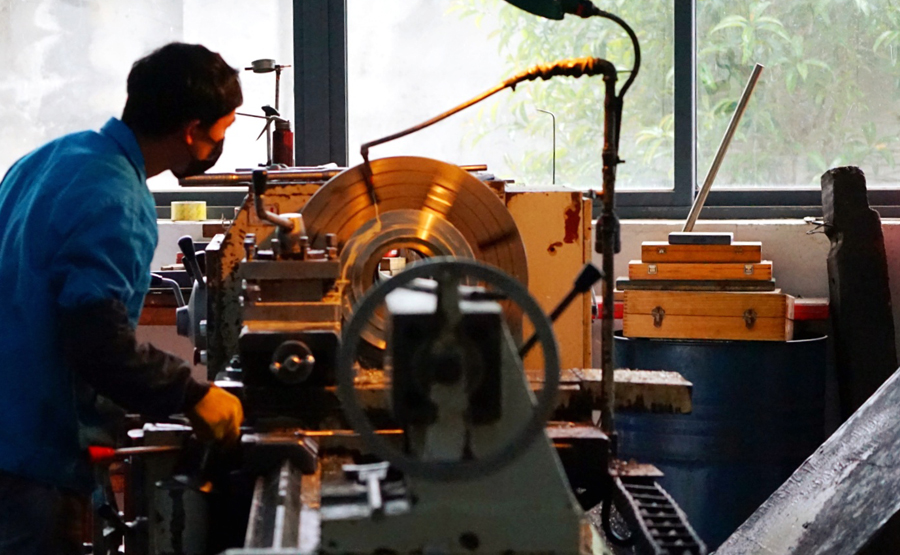

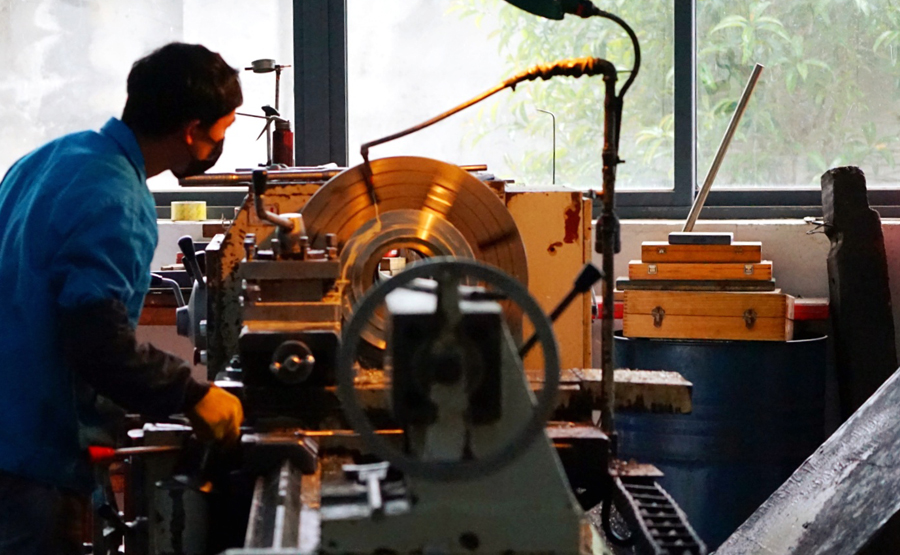

Zhejiang Zhengda Environmental Protection Equipment Co., Ltd.: focusing on Horizontal spiral sedimentation centrifuge, sludge dewatering machine, sludge treatment equipment, centrifugal dewatering machine, sludge dewatering equipment, solid-liquid separation equipment, horizontal spiral centrifuge, centrifuge, mud dewatering machine, mud dewatering equipment, mud treatment equipment, horizontal centrifuge, solid-liquid separator Production, sales and service of various solid-liquid separation equipment. Welcome new and old customers to come for consultation and investigation.

Factory address: No. 812, Jiulong Street, Bihu Town Industrial Zone, Liandu District, Lishui City, Zhejiang Province Telephone: 0578-2788008 Fax :0578-2788681

Email: [email protected] website: //hcsxe.com

Mobile: 15857812218 (Mr. Mao) fifteen billion two hundred and fifty-seven million eight hundred and twenty-six thousand six hundred and nine (Manager Xu) thirteen billion nine hundred and six million seven hundred and eighty-eight thousand three hundred and sixty-seven (Mr. Xu)