Horizontal screw centrifuge The impact of its mechanical part can be divided into adjustable factors and non adjustable factors, which are explained separately. First of all, we understand the principle of its action, and then we can effectively control it in use.

2.1 Non adjustable mechanical factors

A Drum diameter and effective length

The larger the diameter of the drum, the longer the effective length, the larger the effective settlement area, the greater the processing capacity, and the longer the residence time of materials in the drum. At the same speed, the greater the separation factor, and the better the separation effect. But limited by materials, Centrifuge It is impossible to increase the diameter of the drum without limitation, because the maximum allowable speed will decrease with the increase of the diameter, and the centrifugal force will also decrease accordingly. Generally, the diameter of the drum is 200~1000mm, and the length diameter ratio is 3~4. The development of the present horizontal spiral centrifuge tends to be high speed and large length diameter ratio. This kind of equipment can better adapt to the treatment of low concentration sludge, and the sludge has better biscuit degree.

In addition, under the condition of the same processing capacity, the centrifuge with large drum diameter can operate at a lower differential speed. The reason is that the spiral slag conveying capacity of large drum diameter is larger. To achieve the same slag conveying capacity, the centrifuge with small drum diameter must be realized by increasing the differential speed.

B Half cone angle of drum

When the sediment settled on the inside of the centrifuge drum is pushed to the discharge port along the cone end of the drum, it is subject to the downward sliding reflux force due to the centrifugal force. The half cone angle of the rotating drum is an important parameter in the design of the centrifuge. In terms of clarification effect, the cone angle should be as large as possible; In terms of slag conveying and dewatering effects, the cone angle should be as small as possible. Since slag conveying is a necessary condition for the normal operation of the centrifuge, the optimal design must first meet the slag conveying conditions. For materials that are difficult to separate, such as activated sludge, the half cone angle is generally within 6 degrees, so as to reduce the return speed of sediment. For ordinary materials, if the half cone angle is less than 10 degrees, the smooth transportation of sediment can be ensured.

C pitch

The pitch, which is the distance between two adjacent spiral blades, is a very important structural parameter and directly affects the success or failure of slag conveying. When the spiral diameter is fixed, the larger the pitch is, the larger the spiral rise angle is, and the greater the chance of material blocking between spiral blades is. At the same time, large pitch will reduce the number of turns of spiral blades, which will lead to uneven distribution of materials at the cone end of the drum and increase the vibration of the machine. Therefore, for materials that are difficult to separate, such as activated sludge, it is difficult to transport slag. The screw pitch should be smaller, generally 1/5~1/6 of the drum diameter, to facilitate transport. For easily separated materials, the screw pitch should be larger, generally 1/2~1/5 of the drum diameter, to improve the sediment conveying capacity.

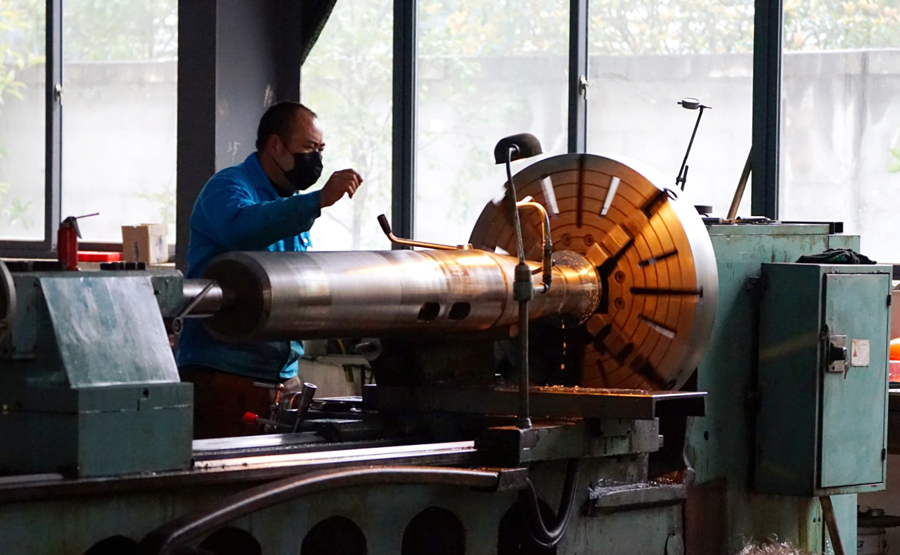

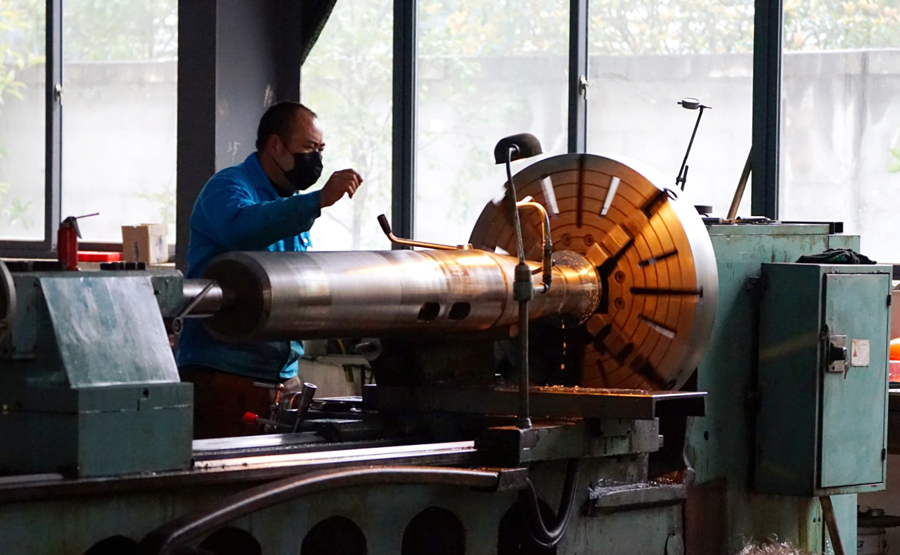

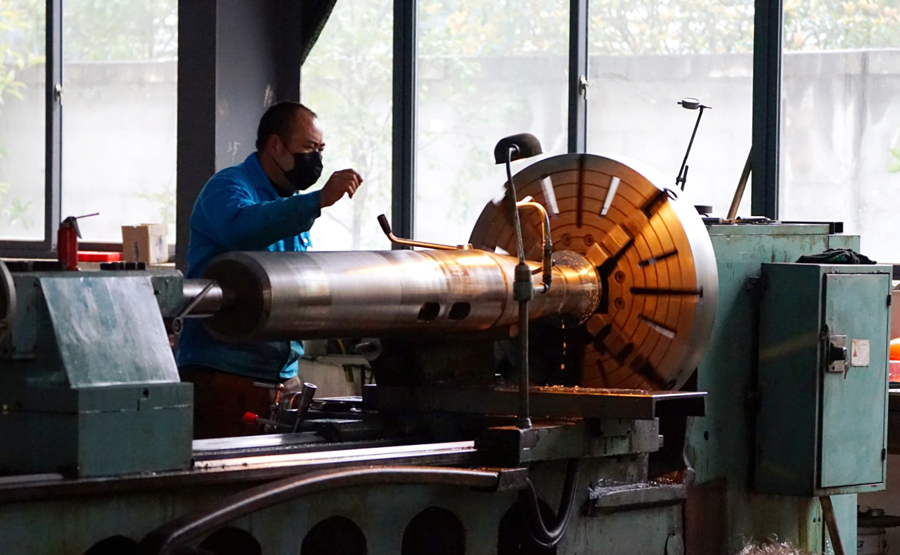

Zhejiang Zhengda Environmental Protection Equipment Co., Ltd.: focusing on Horizontal spiral sedimentation centrifuge, sludge dewatering machine, sludge treatment equipment, centrifugal dewatering machine, sludge dewatering equipment, solid-liquid separation equipment, horizontal spiral centrifuge, centrifuge, mud dewatering machine, mud dewatering equipment, mud treatment equipment, horizontal centrifuge, solid-liquid separator Production, sales and service of various solid-liquid separation equipment. Welcome new and old customers to come for consultation and investigation.

Factory address: No. 812, Jiulong Street, Bihu Town Industrial Zone, Liandu District, Lishui City, Zhejiang Province Telephone: 0578-2788008 Fax :0578-2788681

Email: [email protected] website: //hcsxe.com

Mobile: 15857812218 (Mr. Mao) fifteen billion two hundred and fifty-seven million eight hundred and twenty-six thousand six hundred and nine (Manager Xu) thirteen billion nine hundred and six million seven hundred and eighty-eight thousand three hundred and sixty-seven (Mr. Xu)