Current printing and dyeing Industrial sewage treatment Main methods of

Physical method

1. Adsorption method

Among the physical treatment methods of industrial sewage, adsorption is the most widely used method. This method is to mix the powder or particles of porous materials such as activated carbon and clay with industrial sewage, or let the sewage pass through the filter bed composed of its particles in sewage treatment technology, so that the pollutants in industrial sewage are adsorbed on the surface of porous materials or removed by treatment and filtration.

The activated carbon adsorption method, which is mostly used in the tertiary industrial sewage treatment technology, is mainly used abroad. This sewage treatment technology is very effective in removing dissolved organic matter in water, but it cannot remove colloid and hydrophobic dyes in water, and it only has good adsorption performance for water-soluble dyes such as direct dyes and reactive dyes.

At home, activated diatomite and coal slag are also used to treat the traditional printing and dyeing industrial wastewater. The cost of investment is relatively low, and the decolorization effect is good. Its disadvantage is that the amount of sludge is large, and it is difficult to treat in the follow-up link of sewage treatment technology.

Chemical treatment

1. Coagulation method

It mainly includes coagulation sedimentation method and coagulation gas flotation method. Most of the coagulants used are aluminum salt or iron salt.

The main advantages of coagulation method are simple industrial sewage treatment process, convenient operation and management, low equipment investment, less land occupation, and high decolorization efficiency of hydrophobic dyes; The disadvantages are high operation cost of industrial sewage treatment, large sludge volume, difficult dehydration and poor treatment effect on hydrophilic dyes

2. Oxidation method

Ozone oxidation method can obtain good decolorization effect for most dyes, but it has poor decolorization effect for water insoluble dyes such as vulcanization, reduction and coating. According to the operation experience and results at home and abroad, the decolorization effect of this method is good, but it is difficult to popularize and apply it on a large scale due to the high power consumption.

Photooxidation treatment industry Printing and dyeing wastewater Decolorization efficiency is high, but equipment investment and power consumption need to be further reduced.

3. Biological treatment

Anaerobic aerobic biochar contact oxidation process

The test and practical application show that the treatment effect of anaerobic aerobic biochar process can fully meet the national discharge standard, and further treatment can also be reused, and the sludge of the system tends to self balance.

This process has been adopted by many production plants, and the longest operation time is more than 5 years. The treatment effect is stable, and the sludge has never been discharged, and the excessive growth of sludge in the anaerobic tank has not been found.

4. Anaerobic aerobic biological turntable

The anaerobic biological turntable and aerobic biological turntable are connected in series for industrial use Printing and dyeing wastewater treatment Technology, also achieved good results. In this industrial sewage treatment technology, anaerobic and aerobic sludge separation and return devices are provided respectively, and the surplus sludge of the entire industrial sewage treatment process system returns to the anaerobic biological rotary table. One is to increase the biomass and shorten the total hydraulic retention time, and the other is to digest the excess activated sludge in the system. The industrial sewage treatment process is also characterized by both fixed growth and suspended growth. The COD removal rate and decolorization rate can be further improved by adding flocculants to the rotary table. The industrial sewage treatment process can remove more than 70% of COD, chroma, etc. However, the metal components of the rotary table in the industrial sewage treatment process have corrosion, which needs further research and solution.

5. Treatment method of industrial wastewater from alkali reduction

The alkali decrement wastewater is neutralized with acid to make the pH value reach 4~6, then terephthalic acid is separated, the alkali decrement wastewater is removed, and then mixed with the wastewater from other processes such as refining, printing and dyeing of polyester silk screen printing wastewater. The pH value of the comprehensive wastewater is generally less than 11. In this case, the biochemical method is used for treatment, and then the effluent can meet the national discharge standard after physical and chemical treatment.

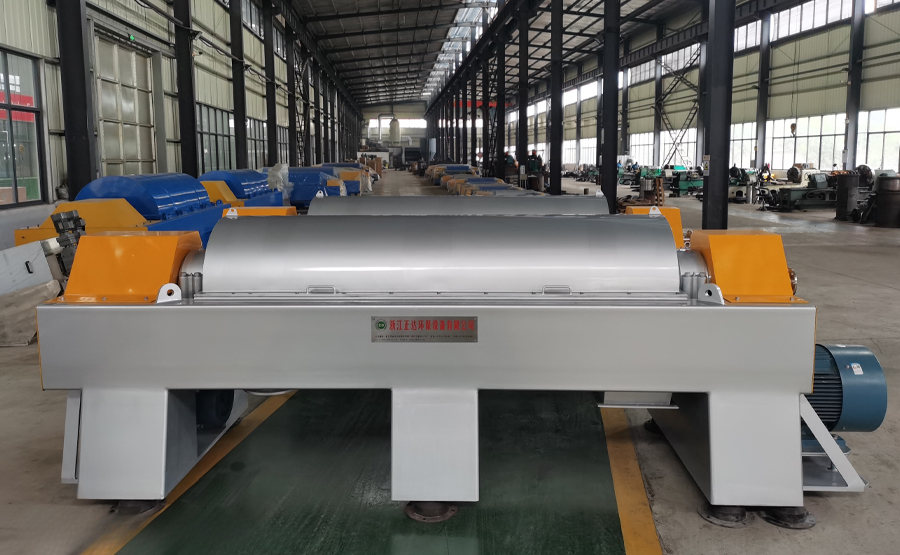

Zhejiang Zhengda Environmental Protection Equipment Co., Ltd.: focusing on Horizontal spiral sedimentation centrifuge, sludge dewatering machine, sludge treatment equipment, centrifugal dewatering machine, sludge dewatering equipment, solid-liquid separation equipment, horizontal spiral centrifuge, centrifuge, mud dewatering machine, mud dewatering equipment, mud treatment equipment, horizontal centrifuge, solid-liquid separator Production, sales and service of various solid-liquid separation equipment. Welcome new and old customers to come for consultation and investigation.

Factory address: No. 812, Jiulong Street, Bihu Town Industrial Zone, Liandu District, Lishui City, Zhejiang Province Telephone: 0578-2788008 Fax :0578-2788681

Email: [email protected] website: //hcsxe.com

Mobile: 15857812218 (Mr. Mao) fifteen billion two hundred and fifty-seven million eight hundred and twenty-six thousand six hundred and nine (Manager Xu) thirteen billion nine hundred and six million seven hundred and eighty-eight thousand three hundred and sixty-seven (Mr. Xu)