In recent years, with the development of social economy and urbanization in China, the expansion of water supply and drainage pipelines and the increase of sewage treatment plants have led to more and more sludge production. However, at present, domestic Sludge treatment The disposal level is relatively low, and the sludge after conventional thickening and dewatering is mainly abandoned, which makes it difficult to meet the requirements of sludge reduction, stabilization, innocuity and recycling. At the same time, it also brings about secondary environmental pollution and difficulties in normal operation of water supply and drainage and sewage treatment.

Some water treatment enterprises have invested some sludge machinery Dehydration equipment However, due to backward technology, the sludge dryness is low and the dewatering effect is not satisfactory. The Opinions of the State Council on the Development of Circular Economy has taken sludge reduction and resource utilization as one of the key links. Therefore, the promotion of harmless, reduced and resourceful utilization of urban sludge has become the focus of common concern of industry experts and the public, and has become the policy goal of local governments after the "12th Five Year Plan". Therefore, sludge treatment and disposal has become a new topic in the process of sewage treatment and environmental remediation, as well as a new task of developing circular economy and building a harmonious society.

Sludge dewatering equipment Changes in:

at home and abroad Sludge treatment equipment The status, problems and trends of technical products are as follows:

-Mechanical dewatering equipment used in domestic water treatment process mainly includes vacuum filtration dewatering, pressure filtration dewatering and centrifugal dewatering. Vacuum filtration dehydration is achieved by applying vacuum on porous filter media to forcibly "suck" water from sludge. Common equipment includes various forms of vacuum drum filter dehydrator. Pressure filtration dehydration is achieved by applying pressure to make water pass through the filter medium. Common equipment includes various types of belt filter press dehydrator and plate and frame filter press. Centrifugal dewatering separates water from sludge particles by centrifugal force to achieve dewatering. Common equipment has various forms Centrifugal dehydrator 。

-The above dehydration equipment has a certain use history, but the specific use situation is very different. Most of the sewage treatment plants built in the early stage use vacuum filter dehydrators. However, because of its high moisture content of sludge cake, high noise, large floor area, and its structure and performance have not been greatly improved, it has rarely been used since the 1980s. The mud cake moisture content of the plate and frame filter press dehydrator is the lowest, so it has been used all the time. However, the equipment is operated intermittently, with low efficiency, tedious operation and heavy maintenance workload, so it is not commonly used, and only used when the mud moisture content is required to be very low. Belt filter press is a commonly used dewatering equipment in recent years. It uses pressure and tension to dewater sludge by applying pressure on the filter cloth. However, the equipment needs to clean the filter cloth frequently, so the backwash water consumption is large, and the secondary sewage generated in the backwash process is increased, so the dewatering effect is not ideal. According to our understanding, some equipment users are very dissatisfied with the dehydration performance of this equipment. The dewatering effect of centrifugal dewatering equipment is relatively good, but the power consumption is large and the noise is also large. From the perspective of noise, it is a large noise pollution equipment. In addition, one of the biggest disadvantages of this equipment is that once a fault occurs, it is difficult to accurately master the shaft balance during maintenance, and maintenance is very difficult. The balance deviation of the central shaft will cause serious damage to the equipment. According to comprehensive analysis, the dehydration equipment used in the original water treatment market is not ideal.

At present, sludge treatment and disposal are faced with many challenges, and the reform of sludge dewatering equipment technology is of great significance for realizing sludge reduction, stabilization, innocuity and resource utilization.

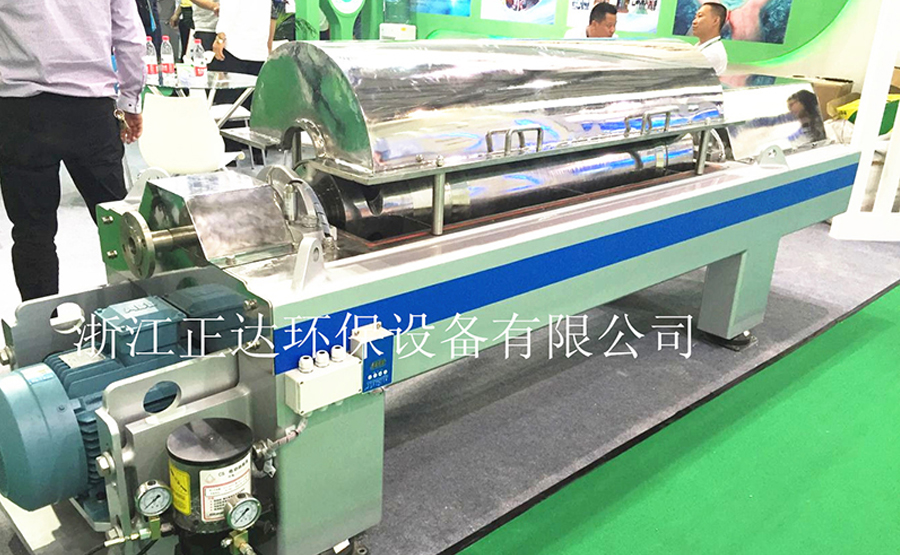

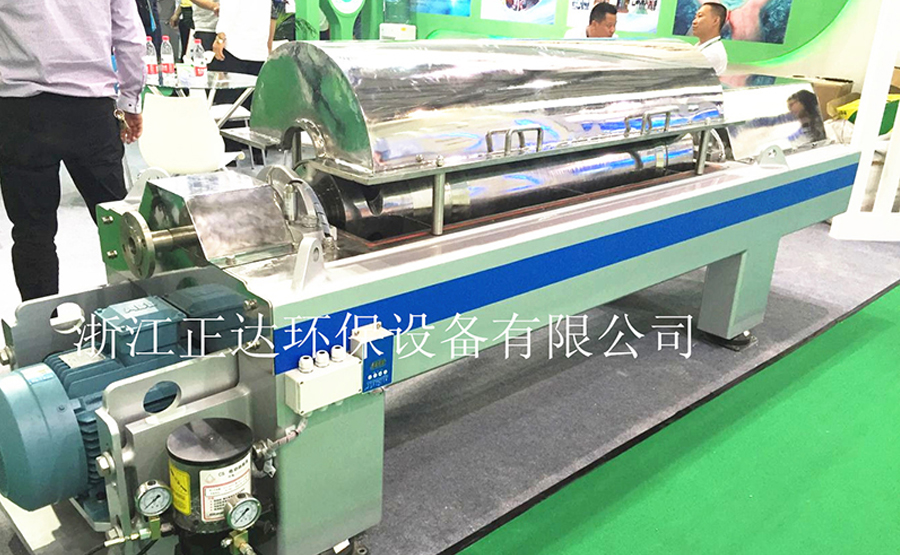

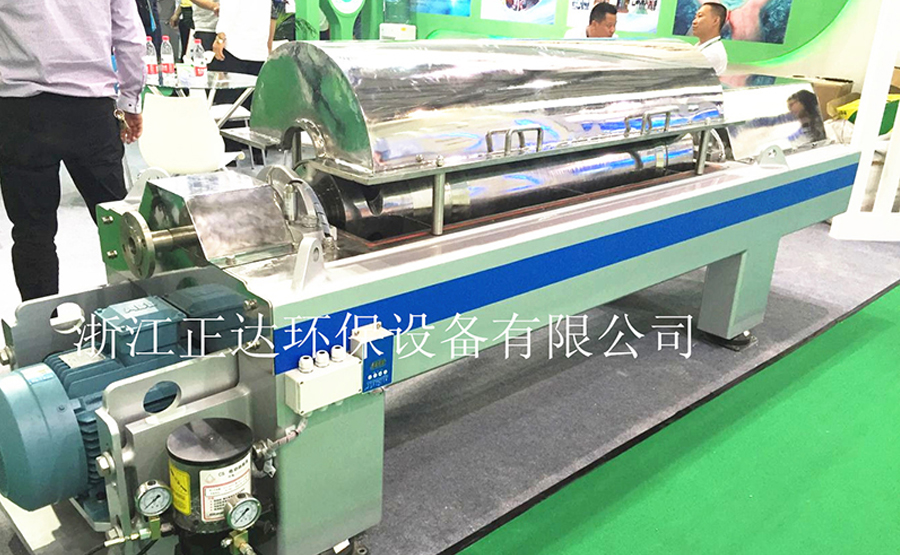

Zhejiang Zhengda Environmental Protection Equipment Co., Ltd.: focusing on Horizontal spiral sedimentation centrifuge, sludge dewatering machine, sludge treatment equipment, centrifugal dewatering machine, sludge dewatering equipment, solid-liquid separation equipment, horizontal spiral centrifuge, centrifuge, mud dewatering machine, mud dewatering equipment, mud treatment equipment, horizontal centrifuge, solid-liquid separator Production, sales and service of various solid-liquid separation equipment. Welcome new and old customers to come for consultation and investigation.

Factory address: No. 812, Jiulong Street, Bihu Town Industrial Zone, Liandu District, Lishui City, Zhejiang Province Telephone: 0578-2788008 Fax :0578-2788681

Email: [email protected] website: //hcsxe.com

Mobile: 15857812218 (Mr. Mao) fifteen billion two hundred and fifty-seven million eight hundred and twenty-six thousand six hundred and nine (Manager Xu) thirteen billion nine hundred and six million seven hundred and eighty-eight thousand three hundred and sixty-seven (Mr. Xu)