Electroplating wastewater Special for processing Centrifuge The main machine is composed of a column cone drum, a screw discharger, a differential system, a bearing seat, a base, a housing, a main and auxiliary motor and an electrical system. Under the action of the powerful centrifugal force generated by the high-speed rotation of the centrifuge, the electroplating wastewater is continuously dehydrated 24 hours a day. The main motor rotates the drum through the V-belt and the planetary gear differential mechanism The drum and screw differential speed generated with the auxiliary motor realize the separation of electroplating wastewater and the pushing function. The centrifuge has two automatic control functions, namely differential speed control and torque control. Since the solid content of electroplating wastewater feed may fluctuate, the differential speed control system is used to ensure the stability of differential speed and the mud dryness. The positive torque control is used to keep the centrifuge load in a stable state, so that the separation effect or the use of flocculant is in the best state, It can ensure the reliable and safe operation of the centrifuge. The centrifuge has excellent sealing performance, and the wastewater separation works in a fully sealed state, making the environment clean.

This machine adopts the most advanced special structural design in the world, especially the high-strength wear-resistant technology. It has many outstanding advantages, such as better performance than ordinary centrifuge, small floor area, high degree of automation, continuous operation, low civil construction investment, low cost of electroplating wastewater separation and treatment, low product moisture, greater treatment capacity, better separation effect, stability and reliability, simple operation (fool type), etc. This product has passed ISO9001 quality system certification. It was also recognized as a national high-tech enterprise in 2010. The products are recognized as high-tech products. The mechanical performance is higher than the standard of JB/T4335-91 Technical Conditions for Spiral Settling Discharge Centrifuge

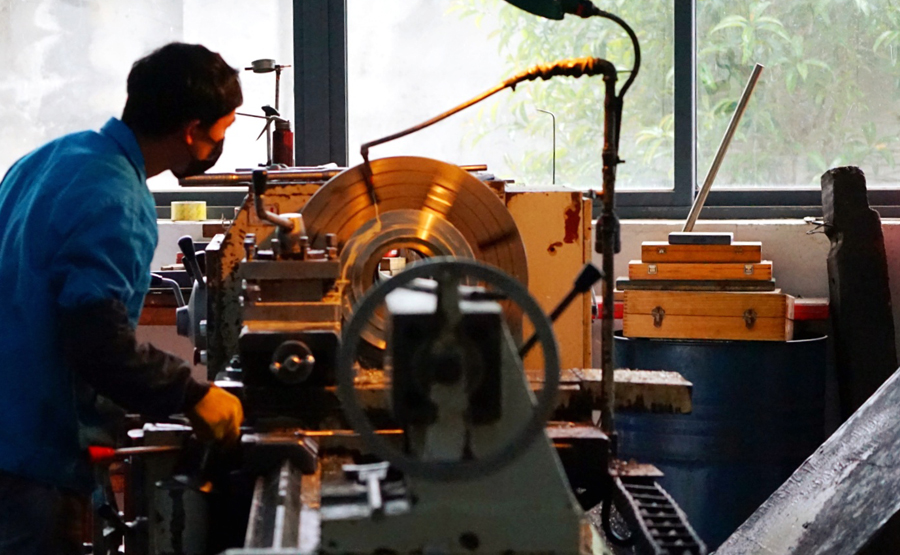

For more than 15 years, we have never stopped moving forward with the development purpose of "excellent quality, first-class service, integrity, mutual benefit and win-win". We have all kinds of advanced processing and testing equipment; There is a research and development team dominated by senior engineers, and a group of excellent employees. Under the leadership of the company, the whole "Zhengda" enterprise is full of vitality. Our company's Electroplating wastewater treatment The production technology of the equipment has reached a new level, and the leading advantage of "more efficient, more professional, more stable and more skilled" will enable Zhengda to "second generation electroplating waste water treatment The "equipment" is brilliant in the field of electroplating wastewater treatment.

Zhejiang Zhengda Environmental Protection Equipment Co., Ltd.: focusing on Horizontal spiral sedimentation centrifuge, sludge dewatering machine, sludge treatment equipment, centrifugal dewatering machine, sludge dewatering equipment, solid-liquid separation equipment, horizontal spiral centrifuge, centrifuge, mud dewatering machine, mud dewatering equipment, mud treatment equipment, horizontal centrifuge, solid-liquid separator Production, sales and service of various solid-liquid separation equipment. Welcome new and old customers to come for consultation and investigation.

Factory address: No. 812, Jiulong Street, Bihu Town Industrial Zone, Liandu District, Lishui City, Zhejiang Province Telephone: 0578-2788008 Fax :0578-2788681

Email: [email protected] website: //hcsxe.com

Mobile: 15857812218 (Mr. Mao) fifteen billion two hundred and fifty-seven million eight hundred and twenty-six thousand six hundred and nine (Manager Xu) thirteen billion nine hundred and six million seven hundred and eighty-eight thousand three hundred and sixty-seven (Mr. Xu)