beneficiation Sludge dewatering machine (Discipline name: horizontal spiral discharge settling type Centrifuge )

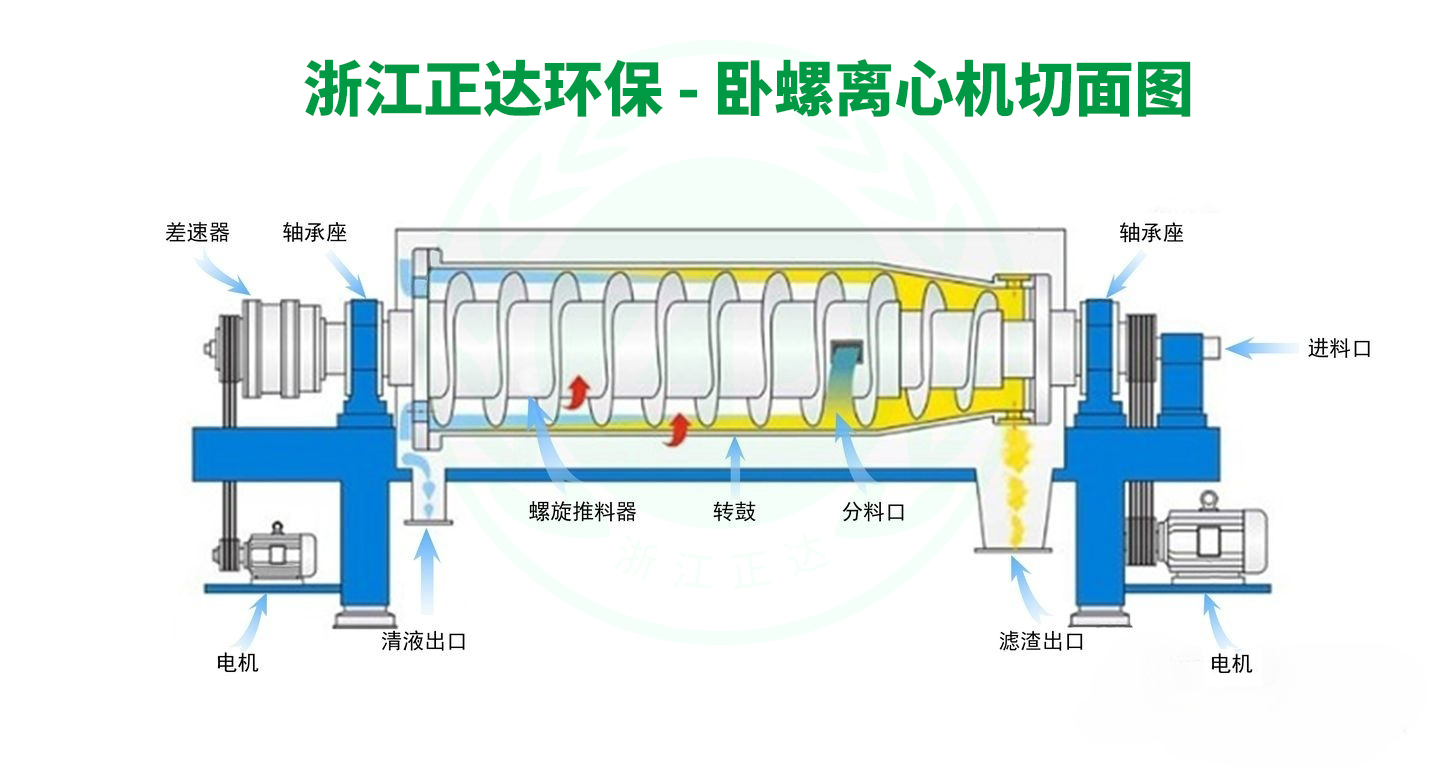

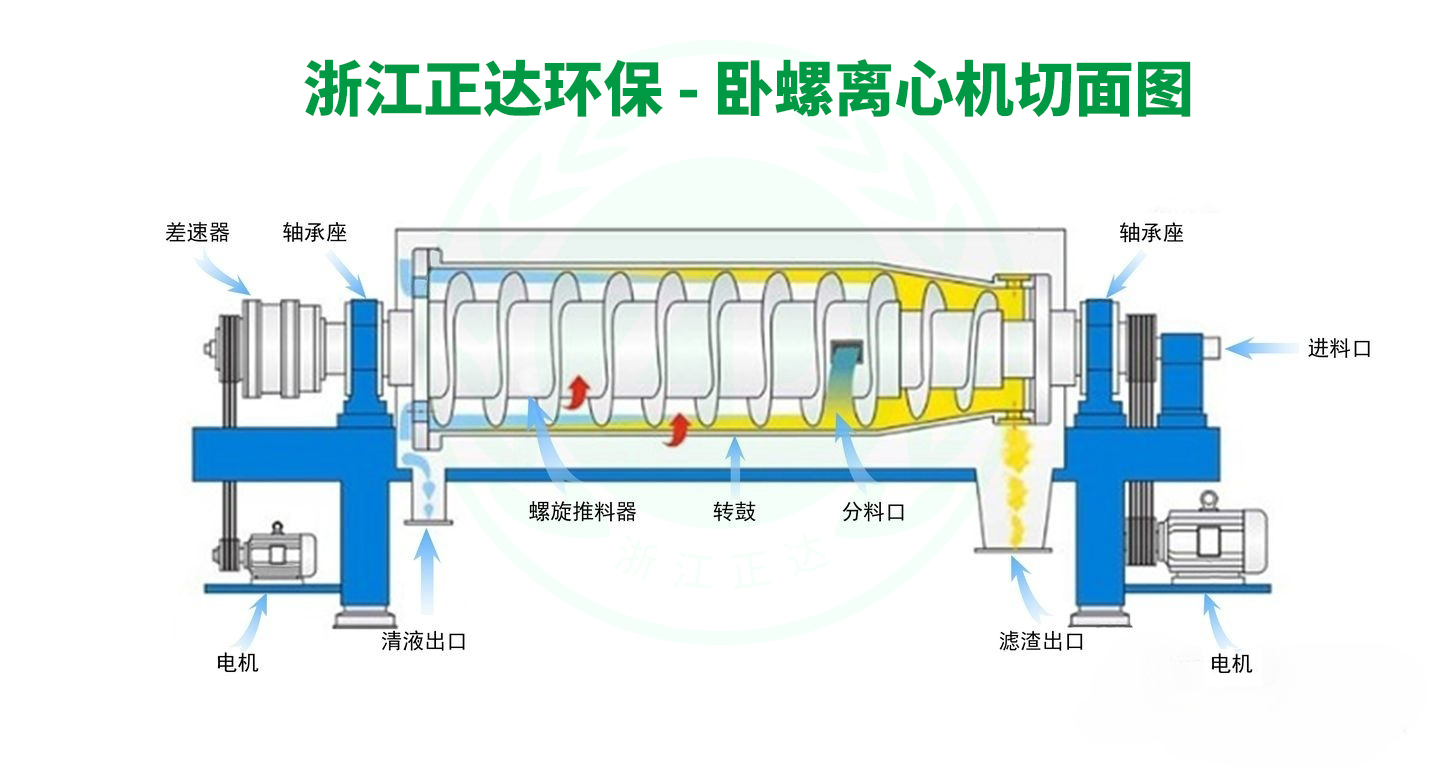

Zhejiang Zhengda Environmental Protection - Horizontal screw centrifuge working principle

The purpose of separation of beneficiation sludge dehydrator is to separate the solids in the mixed fluid whose specific gravity is greater than that of the liquid phase fluid from the liquid phase fluid.

When the mixed liquid has a feed port and enters the inner cavity of the high-speed rotating drum, the solids with large proportion in the mixed liquid will rapidly settle to the inner wall of the drum under the action of centrifugal force, and will be discharged from the drum body by the screw feeder from the solid phase outlet; At the same time, the liquid phase with smaller specific gravity forms an inner liquid ring under the action of centrifugal force, which is discharged from the drum through the liquid overflow port. The rotary drum and the screw feeder run at high speed at the same time. Due to a certain speed difference between the two, the solid objects settled on the drum wall are continuously pushed by the screw feeder to the liquid outlet for discharge, and the whole separation process continues.

Structural schematic diagram of Zhejiang Zhengda Environmental Protection Horizontal Screw Centrifuge

Horizontal screw centrifuge, also known as horizontal screw discharge sedimentation centrifuge, uses the centrifugal acceleration generated by high-speed rotation to rapidly settle the solid particles in the liquid and deposit them on the inner wall of the drum. After the materials are pumped into the cavity through the feed pipe, the drum and the screw conveyor rotate at high speed in the same direction with differential speed, so that the solids are settled on the inner wall of the drum, and then discharged through the screw conveyor. The clarified liquid phase is discharged from the outlet weir at the other end of the drum, so as to realize the continuous feeding, separation and unloading of materials, and finally achieve the effect of solid-liquid separation.

Structural characteristics of Zhejiang Zhengda environmental protection horizontal spiral centrifuge

1. Large length diameter ratio, high speed. Drum cone structure with multiple angles;

2. The feeding screw adopts special anti-wear measures, which can be sprayed with a hard alloy protective layer or inlaid with a hard alloy wear plate;

3. Effectively avoid double rotor high-speed rotation resonance zone phenomenon: within the design speed range, there is no obvious first and second order resonance zone phenomenon when the whole machine is running, and the full vibration intensity of the bearing pedestal is controlled between 2mm/s and 4mm/s. The additional fatigue damage of equipment components caused by high-frequency vibration is avoided.

4. Differential selection: planetary gear or hydraulic differential with heavy load and large transmission ratio shall be selected;

5. Main engine bearing selection: Sweden SKF, Japan NSK and other international first-line brand products of origin shall be selected.

6. Main bearing lubrication system: A, thin oil lubrication, B, grease lubrication

7. Constant temperature inspection: the inspection of all finishing parts of the whole machine is carried out under constant temperature conditions to ensure that the actual processing quality meets the design accuracy requirements.

8. GSRL high-speed feeding device: by adjusting the internal design of the spiral core tube, without reducing the centrifugal acceleration of the original separation solution, the following speed time of materials entering the centrifuge is shortened, the turbulence of swirl is reduced, the effective separation time of materials inside the centrifuge is prolonged, the separation efficiency is improved, and the processing capacity is increased by 15%~25% while the required speed for separation is reduced by 10%~12%. At the same time, it can increase the working pressure inside the centrifuge and inhibit the production of liquid foam.

9. The differential speed and torque can be automatically adjusted with the change of material concentration and flow;

10. The horizontal spiral sedimentation centrifuge with BD plate can concentrate and dewater the primary sedimentation and activated sludge of different proportions and separate the materials difficult to separate.

Zhejiang Zhengda Environmental Protection - application field of horizontal spiral centrifuge

urban sewage | Sewage from urban waterworks | Landfill leachate sewage |

Sewage from urban sewage treatment plant | Sewage from concrete mixing plant |

Municipal sewage | |

Industrial products and wastewater | Magnetic material separation | PVC Resin dehydration |

Crystal separation | Flocculation sedimentation sludge dewatering |

Tire powder separation | Textile chemical fiber wastewater |

Separation of printing and dyeing wastewater | Electroplating wastewater |

Separation of papermaking wastewater | Tar treatment |

Desulfurization wastewater of power plant | Comprehensive sewage of pharmaceutical factory |

Ceramic wastewater separation | Graphite dehydration |

Dewatering of tannery sludge | |

Metallurgical wastewater | Steel smelting wastewater | Lead zinc mine wastewater |

Coal washing wastewater | Manganese mine wastewater |

Mine stone wastewater | Iron ore wastewater |

Fluorite mine wastewater | |

Infrastructure mud | Construction piling mud | River silt |

Tunnel mud | Sand field mud |

Oil and gas | Oil drilling mud separation | Petrochemical industry |

Oil and gas exploration | refining of crude oil |

Food and medicine | Separation of soybean protein | Distiller's grains dehydration |

Fruit juice beverage separation | Brewery wastewater |

Starch dehydration | Dehydration of traditional Chinese medicine residue |

Separation of vegetable oil | Aquatic product processing |

Aquaculture wastewater | Livestock manure | Slaughtering wastewater |

Treatment of biogas slurry and residue | |

Other industries | Paint powder separation | Kaolin separation |

Recycling of plastic scraps | |

Zhejiang Zhengda Environmental Protection - Horizontal Screw Centrifuge Double motor Double frequency conversion Series - Main Technical Parameters

| model | Maximum production capacity (m ³/ h) | Maximum excretion capacity (m ³/ h) | Motor power (Kw) | Weight (KG) | Overall dimensions (L x W x H) (MM) |

| LW - 250 | five | zero point seven | 4-75 | one thousand and one hundred | 2000 x 1150 x 700 |

| LW - 350 | fifteen | one point two | 7.5-15 | one thousand and eight hundred | 2650 x 1300 x 750 |

| LW - 360 | twenty | one point five | 11-22 | two thousand and one hundred | 2850 x 1300 x 750 |

| LW - 450 | thirty | two | 15-37 | three thousand and five hundred | 4060 x 1030 x 1300 |

| LW - 530 | forty-five | five | 22-45 | three thousand and eight hundred | 4030 x 1240 x 14420 |

| LW - 550 | forty-five | four | 18.5-45 | four thousand and five hundred | 4500 x 1240 x 1420 |

| LW - 600 | fifty-five | six | 22-45 | five thousand and two hundred | 4000 x 1300 x 1600 |

| LW - 650 | seventy | eight | 30-75 | eight thousand | 4900 x 1375 x 1650 |

| LW - 750 | eighty-five | ten | 37-90 | nine thousand and five hundred | 5050 x 1450 x 1700 |

| LW - 850 | one hundred | twelve | 37-110 | eleven thousand | 5600 x 1650 x 1800 |

| LW - 1000 | one hundred and fifty | twenty | 55-160 | seventeen thousand | 6200 x 1800 x 1900 |

Note: Reference for equipment manufacturing materials: carbon steel, 304 stainless steel, 321 stainless steel, 316 stainless steel, 2205 two-way steel. Due to the wide range of applications, the local structure of the equipment will change due to the characteristics of materials, and the overall dimensions will also be properly adjusted. Please ask our business contact personnel for the overall dimension drawing of the equipment. At the same time, it can also be customized according to customer needs.